Nicely Machinery presents EG-8002, EG-9000, and EG-8003

Nicely Machinery introduces the EG-8002 series slitter rewinder as well as showcasing EG-9000 and the EG-8003.

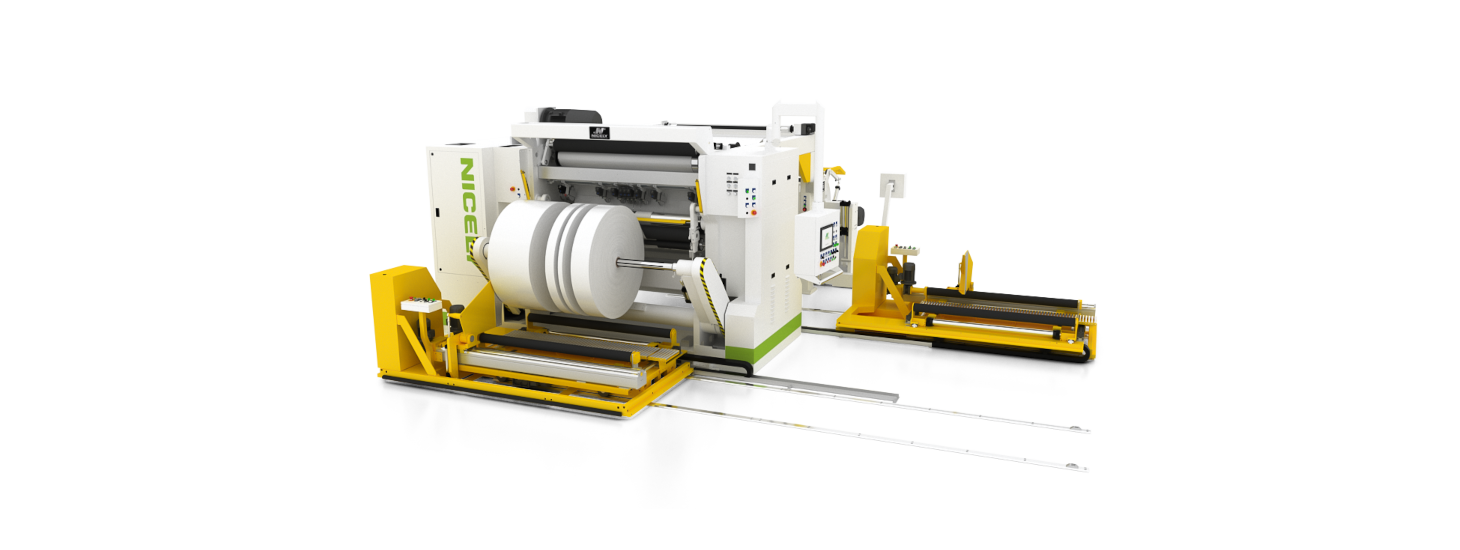

Nicely Machinery is introducing the EG-8002 series slitter rewinder at Labelexpo Europe 2025. Backed by strong customer references in the label industry, the EG-8002 offers expanded capabilities for high-volume production, supporting rewind diameters up to 1200mm and running at speeds up to 800 m/min. Its operator-friendly design features motorized unloading carts, automatic knife positioning, and a PLC control system with HMI touchscreen—streamlining processes and enhancing efficiency. Engineered for precision and reliability, the EG-8002 is ideal for converting labelstock, paper, films, and pharmaceutical materials, meeting the demands of today’s competitive and fast-moving converting environments.

Nicely Machinery is showcasing the EG-9000 spooling slitter rewinder at Labelexpo Europe 2025. Designed for ultra-narrow width slitting and high-speed spooling, this model is ideal for processing adhesive tapes, Alu/PET composite materials, and functional films or foams. With a minimum slit width of 0.8mm and speeds up to 300 m/min, the EG-9000 features precision tension control, modular spooling units, and a traverse winding system. Built for converters requiring extended product lengths and reduced downtime, the EG-9000 delivers consistent roll quality, enhanced productivity, and exceptional performance in demanding narrow-web applications.

Nicely Machinery is presenting the EG-8003 primary slitter rewinder at Labelexpo Europe 2025. It supports widths up to 7800mm, speeds up to 800 m/min, and rewind diameters up to 1200mm. Engineered for large-scale film converting, the machine features servo-driven individual winders that provide precise tension control and superior roll quality. The EG-8003 commonly integrates automatic knife positioning, motorized web threading, energy-efficient servo motors, and real-time tension monitoring. Designed for high-output flexible packaging operations, it minimizes waste, maximizes uptime, and delivers consistent, high-speed performance in demanding production environments.

Stay up to date with latest free email updates

You'll get about two emails per month. We'll never share your address.

Related news articles

- Review prices and deadlines

- Book your tickets

- Attend the event