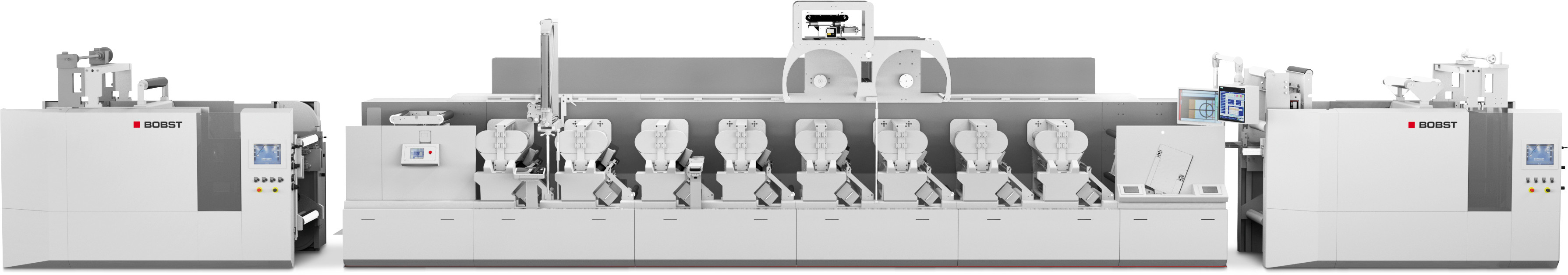

The BOBST M6 press offers a combination of in-line UV Flexo, REVO DigiFlexo and the revolutionary V-Flower print unit for the highest print quality, productivity and hea... More

The BOBST M6 press offers a combination of in-line UV Flexo, REVO DigiFlexo and the revolutionary V-Flower print unit for the highest print quality, productivity and health safety for food packaging. Up to 95% press uptime on all substrates with on-the-fly job changeovers completed in one minute while the machine is running. The M6 will also feature the BOBST DigiMountTM fully automated flexo plate mounting system, which features advanced electronics for improved speed and accuracy of plate mounting.