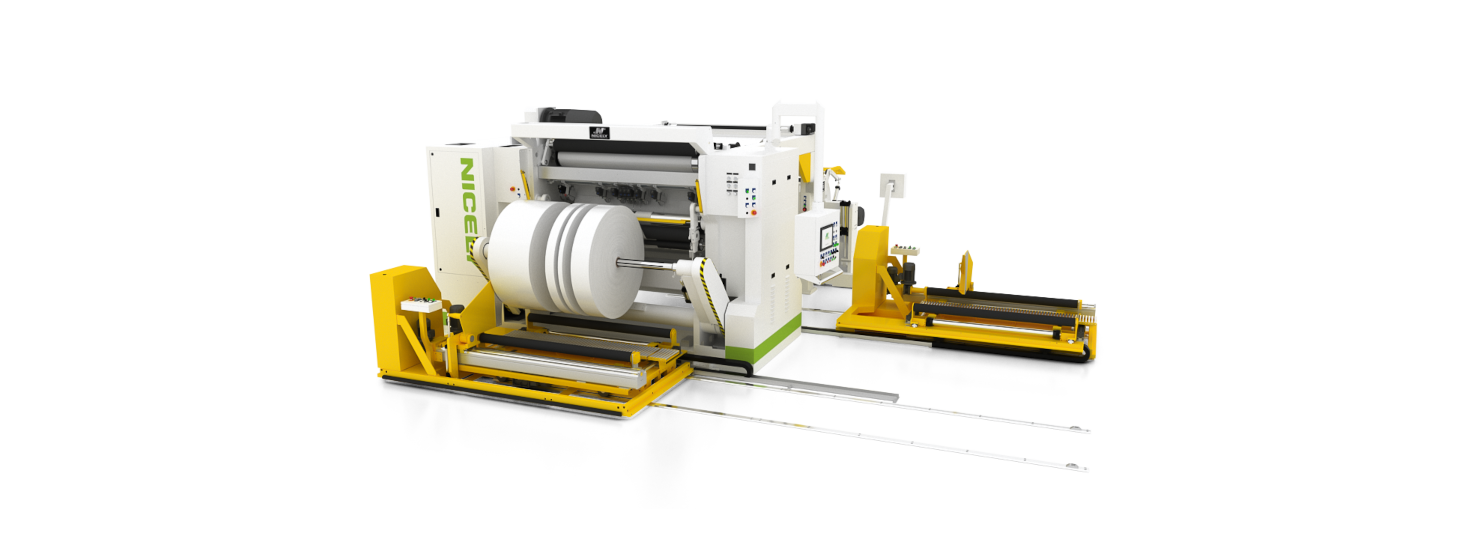

Nicely Machinery presents EG-8002, EG-9000, and EG-8003

Nicely Machinery introduces the EG-8002 series slitter rewinder as well as showcasing EG-9000 and the EG-8003.

Nicely Machinery is introducing the EG-8002 series slitter rewinder at Labelexpo Europe 2025. Backed by strong customer references in the label industry, the EG-8002 offers expanded capabilities for high-volume production, supporting rewind diameters up to 1200mm and running at speeds up to 800 m/min. Its operator-friendly design features motorized unloading carts, automatic knife positioning, and a PLC control system with HMI touchscreen—streamlining processes and enhancing efficiency. Engineered for precision and reliability, the EG-8002 is ideal for converting labelstock, paper, films, and pharmaceutical materials, meeting the demands of today’s competitive and fast-moving converting environments.

Nicely Machinery is showcasing the EG-9000 spooling slitter rewinder at Labelexpo Europe 2025. Designed for ultra-narrow width slitting and high-speed spooling, this model is ideal for processing adhesive tapes, Alu/PET composite materials, and functional films or foams. With a minimum slit width of 0.8mm and speeds up to 300 m/min, the EG-9000 features precision tension control, modular spooling units, and a traverse winding system. Built for converters requiring extended product lengths and reduced downtime, the EG-9000 delivers consistent roll quality, enhanced productivity, and exceptional performance in demanding narrow-web applications.

Nicely Machinery is presenting the EG-8003 primary slitter rewinder at Labelexpo Europe 2025. It supports widths up to 7800mm, speeds up to 800 m/min, and rewind diameters up to 1200mm. Engineered for large-scale film converting, the machine features servo-driven individual winders that provide precise tension control and superior roll quality. The EG-8003 commonly integrates automatic knife positioning, motorized web threading, energy-efficient servo motors, and real-time tension monitoring. Designed for high-output flexible packaging operations, it minimizes waste, maximizes uptime, and delivers consistent, high-speed performance in demanding production environments.

Rimani aggiornato con gli ultimi aggiornamenti email gratuiti

Riceverai circa due email al mese. Non condivideremo mai il tuo indirizzo.

Related news articles

Inizia il tuo percorso qui

3 semplici passi per registrarti e partecipare

- Rivedi i prezzi e le scadenze

- Prenota i tuoi biglietti

- Partecipa all'evento